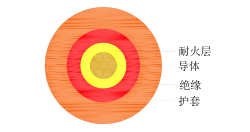

0.6/1kv halogen-free low smoke radiation cross-linked polyolefin insulation

Halogen-free low-smoke polyolefin sheathed fire-resistant power cable

1. High-silica phlogopite tape with a nominal thickness of 0.14mm for the refractory layer

l Double-layer high-silicon gold mica tape with overlap cover greater than 45%

Satisfy:

BS 6387:2013 950℃,0.6/1.0kV,180min,CWZ(applicable to Cable Diameter Φ≤20mm)

BS 8491:2008 950℃,0.6/1.0kV,180min,CWZ(for cable diameters Φ>20mm)

Superior performance:

Under the condition of fire, the power can be continuously electrified for more than 6 hours to maintain the integrity of the circuit.

After the combustion cable withstand voltage test: AC 4000V/5min.

l Single-layer high-silicon gold mica tape with over 30% overlap

Satisfy:

IEC 60331-1:2009 830℃,0.6/1.0kV, 120min,for fire, impact, spray (applicable to cable diameter φ>20mm)

IEC 60331-2:2009 830℃,0.6/1.0kV,120min,for fire, impact, shower (applicable to cable diameter Φ≤20mm)

Superior performance:

Under the condition of fire, the power can be continuously electrified for more than 6 hours to maintain the integrity of the circuit.

After the combustion cable withstand voltage test: AC 2000V/5min.

2. Flame-retardant performance when the cable is burned:

a. Meet the vertical flame spread of a single cable (GB/T 18380.12-2008/IEC 60332-1-2:2004);

b. Meet the GB/T 18380 stipulated bunched cable vertical burning test.

(GB/T 18380.33-2008/IEC60332-3-22: 2000 Class A -product structure can be telephone consultation,

GB/T 18380.34-2008/IEC60332-3—23:2000 Class B)

3.The cable structure is simple and effective

example:

Standard section mm² | Conductor type

| conductor number/diameter

| Conductor outer diameter mm | 20°C Conductor DC Resistance ≤ Ω/km

| Cable approximate outside diameter mm

| Approximate weight of cable kg/km

|

1*2.5 | 1 | 1/1.78 | 1.78 | 7.41 | 6.7 | 71 |

2 | 7/1.05 | 2.04 | 7.41 | 7.0 | 76 |

5 | 50/0.25 | 2.04 | 7.98 | 7.0 | 75 |

1*16 | 2 | 7/1.7 | 5.10 | 1.15 | 10.7 | 249 |

5 | 126/0.40 | 5.18 | 1.21 | 10.8 | 250 |

1*10 | 2 | 7/1.35 | 4.05 | 1.83 | 9.5 | 178 |

5 | 84/0.40 | 4.23 | 1.91 | 9.7 | 186 |

1*6 | 1 | 1/2.76 | 2.76 | 3.08 | 7.7 | 114 |

2 | 7/1.05 | 3.15 | 3.08 | 8.2 | 123 |

5 | 84/0.30 | 3.17 | 3.30 | 8.2 | 122 |